Equipment workflow:

Entering the plate, heating up, holding pressure, stress relief, cooling, and taking out the plate.

Equipment Usage/Function Description:

Power is transmitted to the material rack, leveling machine feeding control seat, and other parts through the electrical control box, and then low-voltage DC is used on the control seat

The on/off control of the positive voltage and zero ground wire of the frequency converter is timed to achieve the final effect of leveling the board after heating.

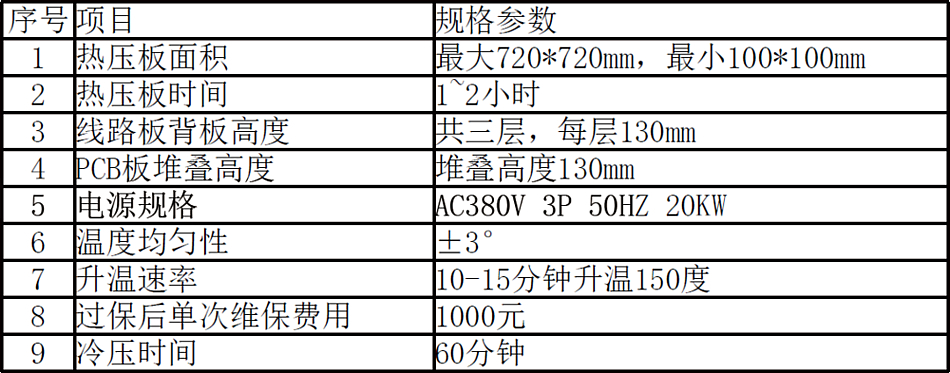

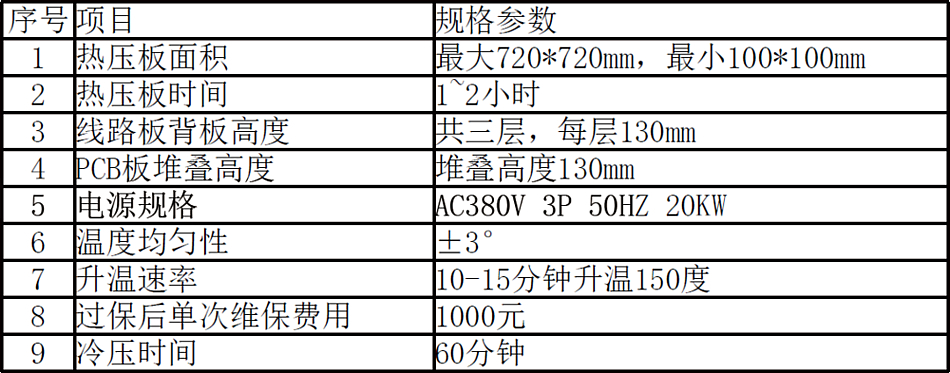

Equipment specifications and parameters

PCB board stacking height: stacking height of 130mm.

Backboard height of circuit board: There are three layers in total, with each layer measuring 130mm.

Hot press plate mechanism: adopts an external pneumatic cylinder.

Temperature control: High precision PID automatic calculation combined with SSR temperature control system ensures uniform temperature.

Pressure control: Three sets of individual independent control pressure regulating valves are used, and the pressure can be set separately.

Wind mode: Double door horizontal air supply circulation heating, uniform temperature. The highest temperature is 160 degrees.

Power protection: Install reverse phase protection device.

Dimensions: Length 1430mm * Width (Depth) 945mm * Height 1990mm

Hot press plate area: maximum 730 * 730mm, minimum 100 * 100mm

Hot pressing time: 120-150 minutes

Power specification: AC380V 3P 50HZ 20KW

Phone: 0755-27387080

Phone: 0755-27387080 Mobile: 13609613568

Mobile: 13609613568 Contact: Mr. Su

Contact: Mr. Su Email: sysu@sanyingtech.com

Email: sysu@sanyingtech.com Website: www.fairfoxeon-org.com

Website: www.fairfoxeon-org.com Address: Dahong Technology Innovation Park, No. 48 Xinyu Road, Xinqiao Street, Bao'an District, Shenzhen

Address: Dahong Technology Innovation Park, No. 48 Xinyu Road, Xinqiao Street, Bao'an District, Shenzhen