This series of dehumidifiers can simulate various temperature and humidity environments, suitable for adaptability testing of power supplies, photovoltaics, electronic and electrical equipment, instruments and other products, components and materials during storage, transportation and use in high and low temperature alternating humid and hot environments; It is a reliability testing equipment for cold, heat, moisture and dry resistance tests and quality control engineering of various photovoltaic products, electronics, electricians, electrical appliances, plastics, foam cotton and other raw materials and devices; Specially suitable for high temperature, low temperature, and moisture cycling tests of capacitors, variable frequency vehicle circuit boards, optical fibers, LCDs, crystals, inductors, PCBs, batteries, computers, and other products.

Product scope of applicationThis series of dehumidifiers can simulate various temperature and humidity environments, suitable for adaptability testing of power supplies, photovoltaics, electronic and electrical equipment, instruments and other products, components and materials during storage, transportation and use in high and low temperature alternating humid and hot environments; It is a reliability testing equipment for cold, heat, moisture and dry resistance tests and quality control engineering of various photovoltaic products, electronics, electricians, electrical appliances, plastics, foam cotton and other raw materials and devices; Specially suitable for high temperature, low temperature, and moisture cycling tests of capacitors, variable frequency vehicle circuit boards, optical fibers, LCDs, crystals, inductors, PCBs, batteries, computers, and other products.

Satisfying various parameters such as reliability and stability performance in harsh environments will provide you with a basis for predicting and improving product quality and reliability. Widely applicable to industries such as electronic power supply, military, plastics, hardware, optoelectronics, chemical, etc., such as electronic components, LED lamps, crystals, motors, inductors, PCBs, automotive parts, mobile phones, computers, rubber, metals, etc., under virtual climate environment temperature and humidity combination conditions (high and low temperature operation&storage, temperature cycling, high temperature and high humidity, low temperature and low humidity, condensation testing, etc.), to detect whether the adaptability and characteristics of the product itself have changed.

Control methods and characteristicsBalanced Temperature and Humidity Control System (BTHC), with P I. D. Control SSR in a way that ensures the heating and humidification capacity of the system is equal to the moisture and heat loss, ensuring long-term stable use.

Refrigerant servo valve flow calculation control. Energy saving by 30%, with a sleep function for idle time, saving more than 50% energy.

Controller anti electromagnetic interference certified by SGS; Equipped with software matching for numbers 32 and above, it has the ability to perform multiple development and software upgrades.

Defrosting cycle (800 cycles of defrosting once, each defrosting cycle is guaranteed to be within 2 hours, and the integration test achieves 25% energy saving).

Meet the standardsGB/T2423.2-89 High temperature test method Bb

GB2423.1-89 Test A: Low temperature test method 6

IEC60068-2-1 Low temperature test method Ab

GJB150.4-1986 Low temperature test

EIA-364-59 Low Temperature Test

IEC60068-2-38 Temperature cycling

IEC60068-2-78 Constant Damp Heat

MIL-STD-202G-103B Humidity Test

IEC60068-2-30 Damp Heat Temperature Cycle

GB-15322 Standard for Combustible Gas Detectors

GB-16808 Standard for Combustible Gas Alarm Controllers

GJB150.4-86 Environmental Test Methods for Military Equipment - Low Temperature Test

GJB150.3-86 Environmental Test Methods for Military Equipment - High Temperature Test

GB/T2423.34-2005 Temperature and Humidity Combined Cycle Test Method

Equipment performanceRefers to air-cooled at room temperature of 20 ℃ or water-cooled at water temperature of 25 ℃,

When unloaded

Temperature range: adjustable from 0 ℃ to 150 ℃

Temperature fluctuation: ≤± 0.5 ℃

Temperature uniformity: ≤± 1 ℃

Heating time: Average of 4 ℃ per minute (when unloaded)

Cooling time: An average of 1 ℃ per minute (when unloaded)

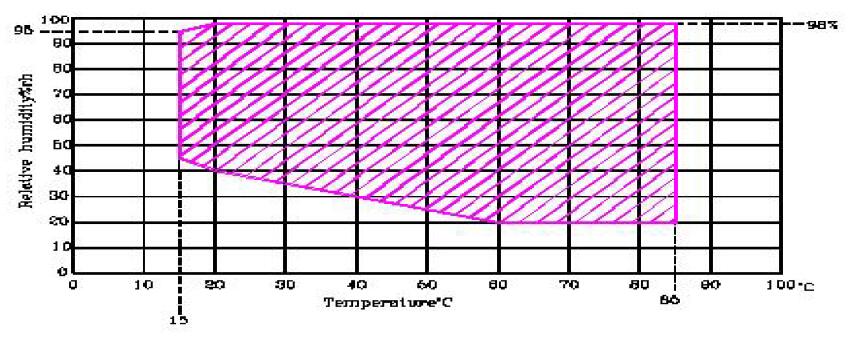

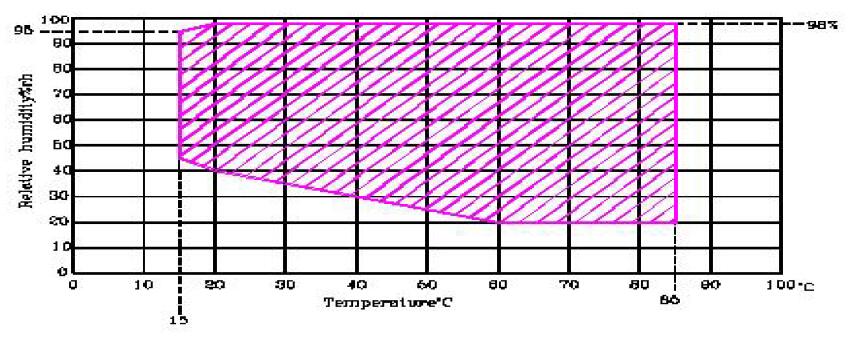

Humidity range: 20% to 98% R.H

Humidity fluctuation: ± 2.5% R.H

Humidity deviation: ≤± 2%

Temperature and humidity control range

Special specifications can be customized

Inner box material: SUS # 304 heat-resistant, cold resistant, corrosion-resistant mirror stainless steel plate (1.2mm thick)

Outer box material: SUS # 304 stainless steel plate (optional) electrolytic steel plate spray coating

Thermal insulation material: imported high-strength fireproof PU foam insulation material, rigid polyurethane foam glass fiber.

Test hole: one ¢ 50mm hole on the left side of the body, and one plug (inlet holes for power and signal lines, which can be powered on for testing)

Box door: Single panel door, single window, left opening, handle on the right-hand side

350 × 250 × 40 mm three-layer vacuum tempered glass (with heating and electricity to prevent fog from blocking the window), and equipped with lighting fixtures (Philips 20W)

Flat embedded handle

Rear button: SUS # 304

Sample placement rack: 2 SUS304 # storage racks, equipped with 4 sets of movable wheels (for easy movement) and a flat water angle cup (to adjust the balance of the machine body).

Touch screen temperature and humidity controller for control system (TIME880)

Phone: 0755-27387080

Phone: 0755-27387080 Mobile: 13609613568

Mobile: 13609613568 Contact: Mr. Su

Contact: Mr. Su Email: sysu@sanyingtech.com

Email: sysu@sanyingtech.com Website: www.fairfoxeon-org.com

Website: www.fairfoxeon-org.com Address: Dahong Technology Innovation Park, No. 48 Xinyu Road, Xinqiao Street, Bao'an District, Shenzhen

Address: Dahong Technology Innovation Park, No. 48 Xinyu Road, Xinqiao Street, Bao'an District, Shenzhen